Soda Production Dashboard

تفاصيل العمل

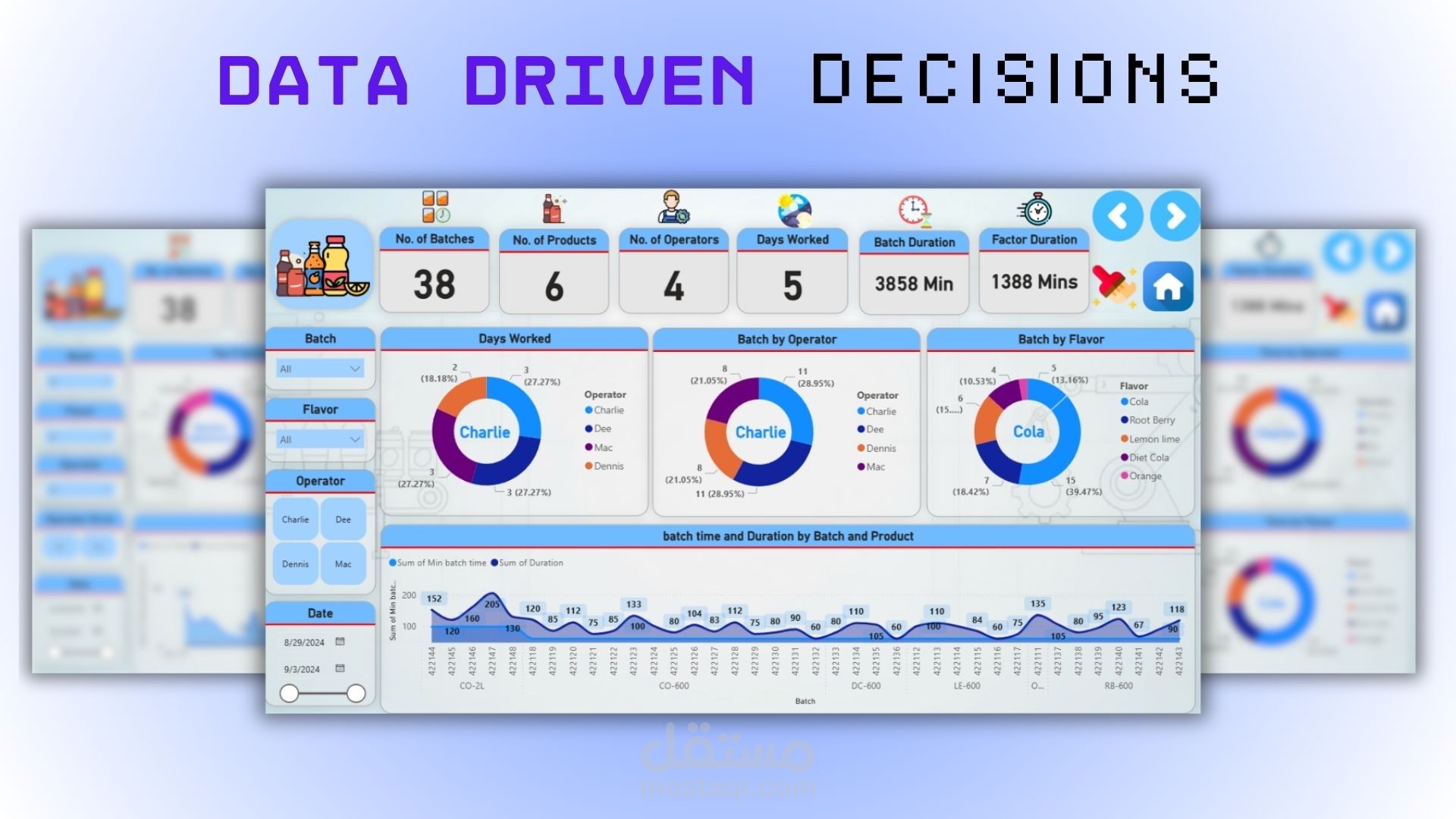

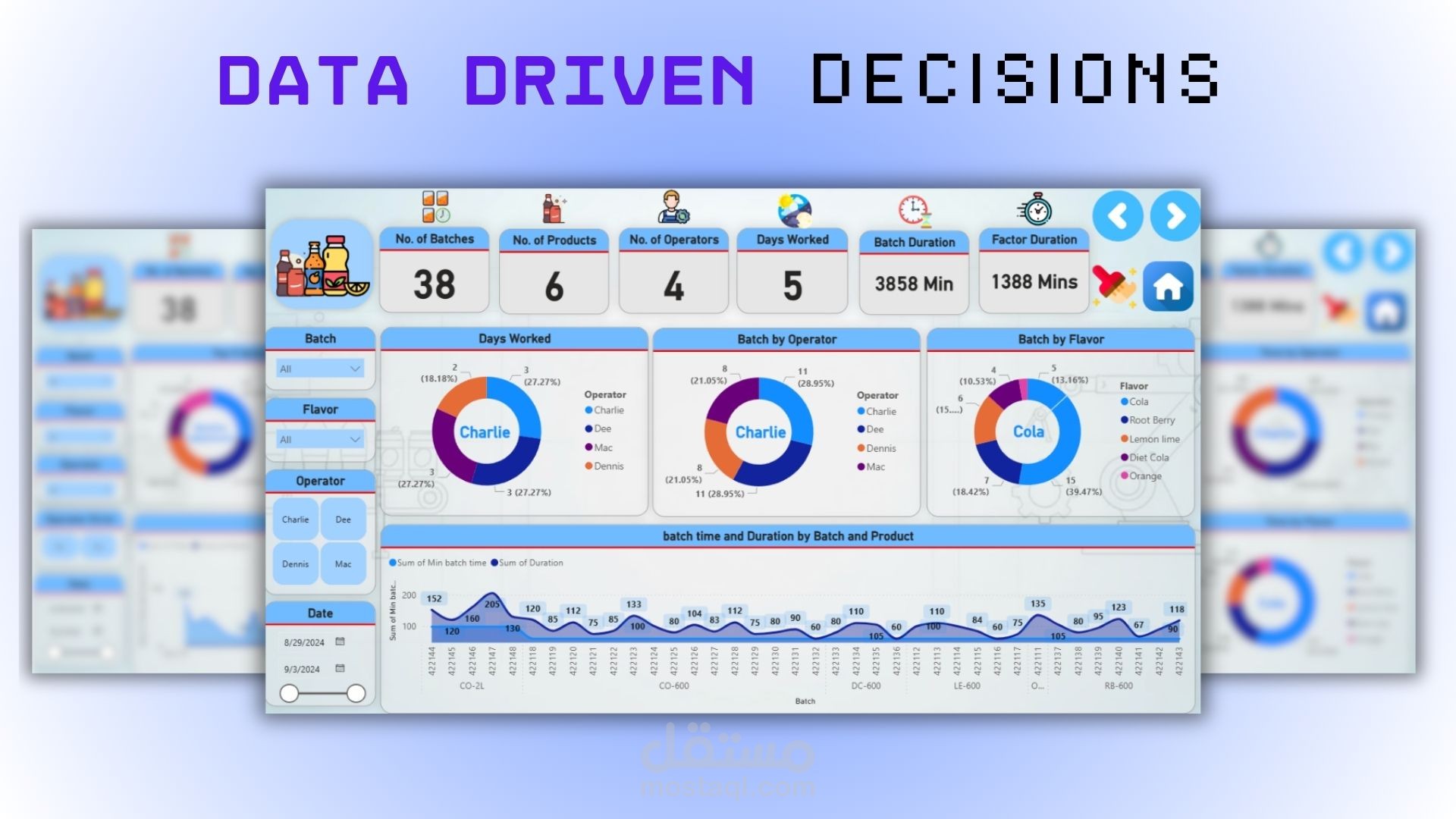

This Dashboard analyzes 5 days of production, involving 4 operators producing 6 different products across 38 batches. The analysis highlights significant downtime issues, primarily centered around one flavor and machine reliability.

Key Performance Insights

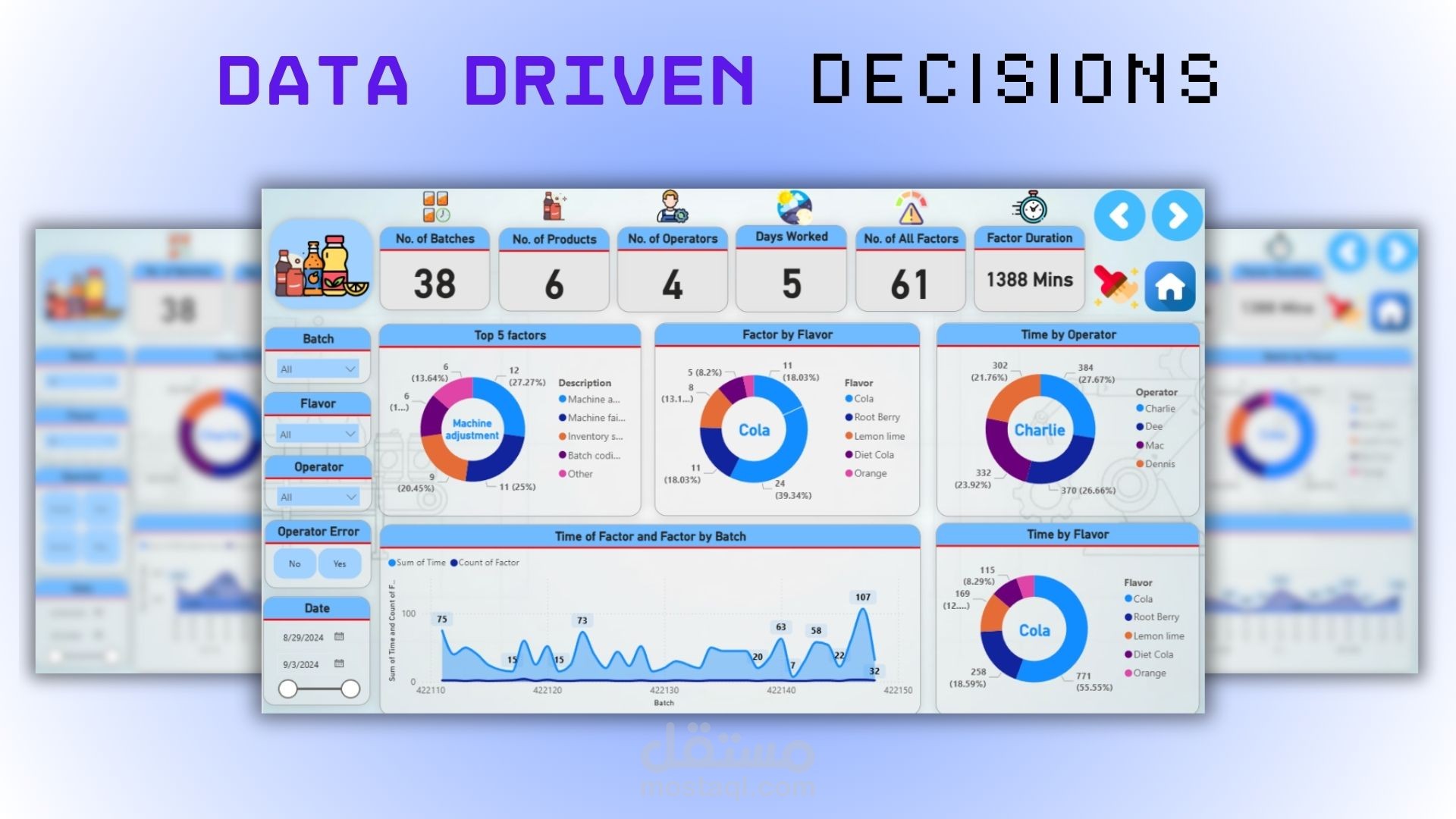

Downtime is High: Total factor (downtime) duration was 1388 minutes from 61 events.

Top Problem Flavor: Cola: Cola is the product with the most deficiency and accounted for 55.55% (771 minutes) of the total factor time. It was associated with approximately 35 errors.

Top Downtime Causes: The two leading factors causing downtime are Machine adjustment (27.27%) and Machine failure (25%). Machine adjustment is noted as a human factor, while failure is a machine issue.

Operator Performance: Charlie and Dee are the highest producers (11 batches each) and also the top two operators with errors. Mac worked 3 days but only made 8 batches, indicating lower efficiency compared to Dennis, who made 8 batches in only 2 days.

Core Recommendations

The primary need is to address deficiencies in the Cola production process and overall machine health.

Machine Audit: Immediately schedule a maintenance audit, focusing on the equipment used for the Cola flavor to investigate frequent failures and needed adjustments.

Process Standardization: Establish a single best-practice Standard Operating Procedure (SOP) for Cola changeover to minimize necessary machine adjustments, regardless of the operator.

Operator Training: Operators should be better trained to reduce errors.