تصميم ميكانيكي

تفاصيل العمل

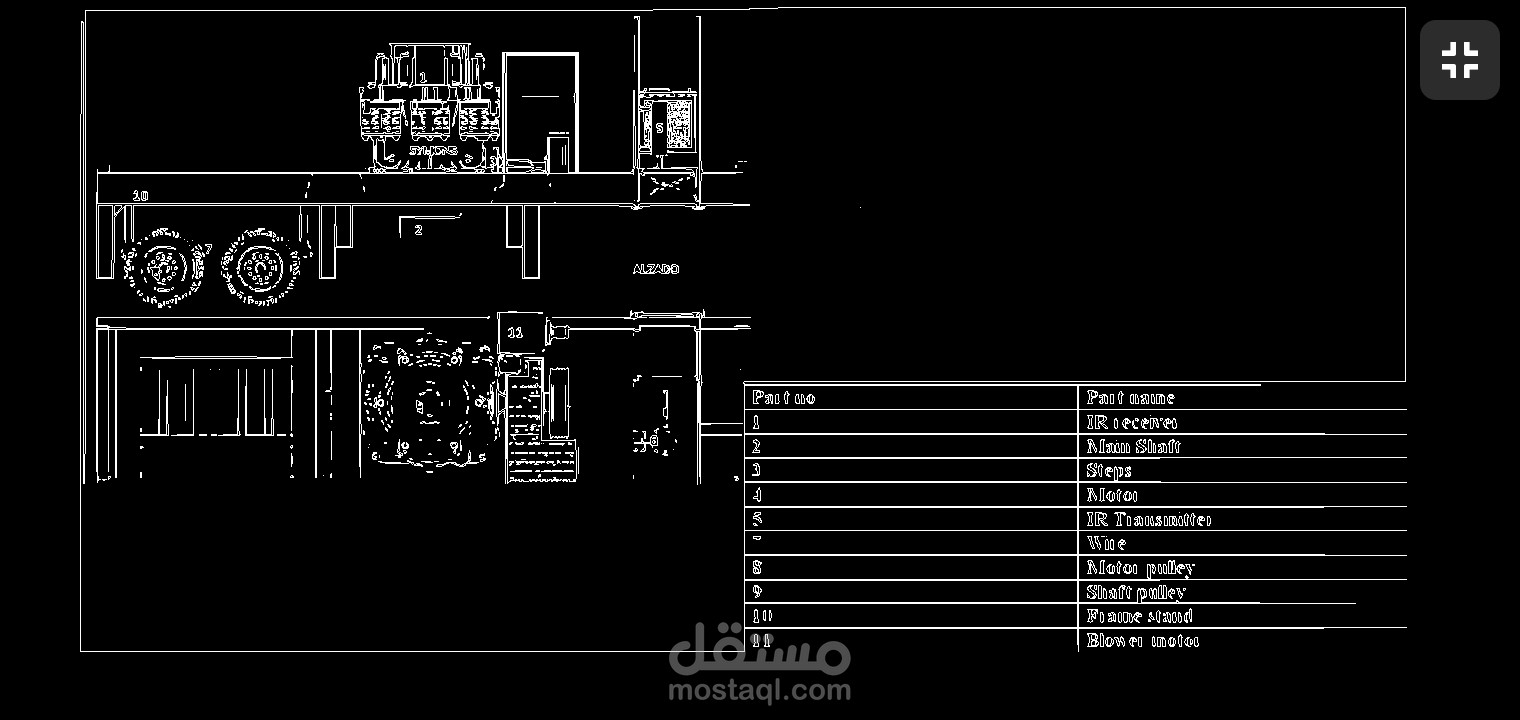

Polishing is a type of surface machining that produces a high-quality finished product surface. It's a multi-step procedure, with each stage employing a finer abrasive. The goal of this study is to design and build a polishing machine that can conduct many polishing processes. During the polishing process, there will be no idle time. The machine is made up of There are four spindle heads, each with its own flap wheel. The flap wheels can be raised or lowered. Lower the polishing pressure based on the size of the item to be polished. Three different types of rollers were used. A heat-resistant rubber-coated mild steel roller, a hylam roller, and a nylon roller are included in the machine. roller. To fix and hold the work piece , a pneumatic clamping mechanism was installed at the feeder.

The following methodology was used in the production of this polishing equipment. The polishing machine's primary construction is divided into two parts. various components as well as many processes Fabrication was completed first, followed by the assembly stage. step by step In addition, the many step-by-step procedures in order to This polishing machine has been streamlined and prepared

ملفات مرفقة

بطاقة العمل

| اسم المستقل | Emoo J. |

| عدد الإعجابات | 0 |

| عدد المشاهدات | 16 |

| تاريخ الإضافة | |

| تاريخ الإنجاز |