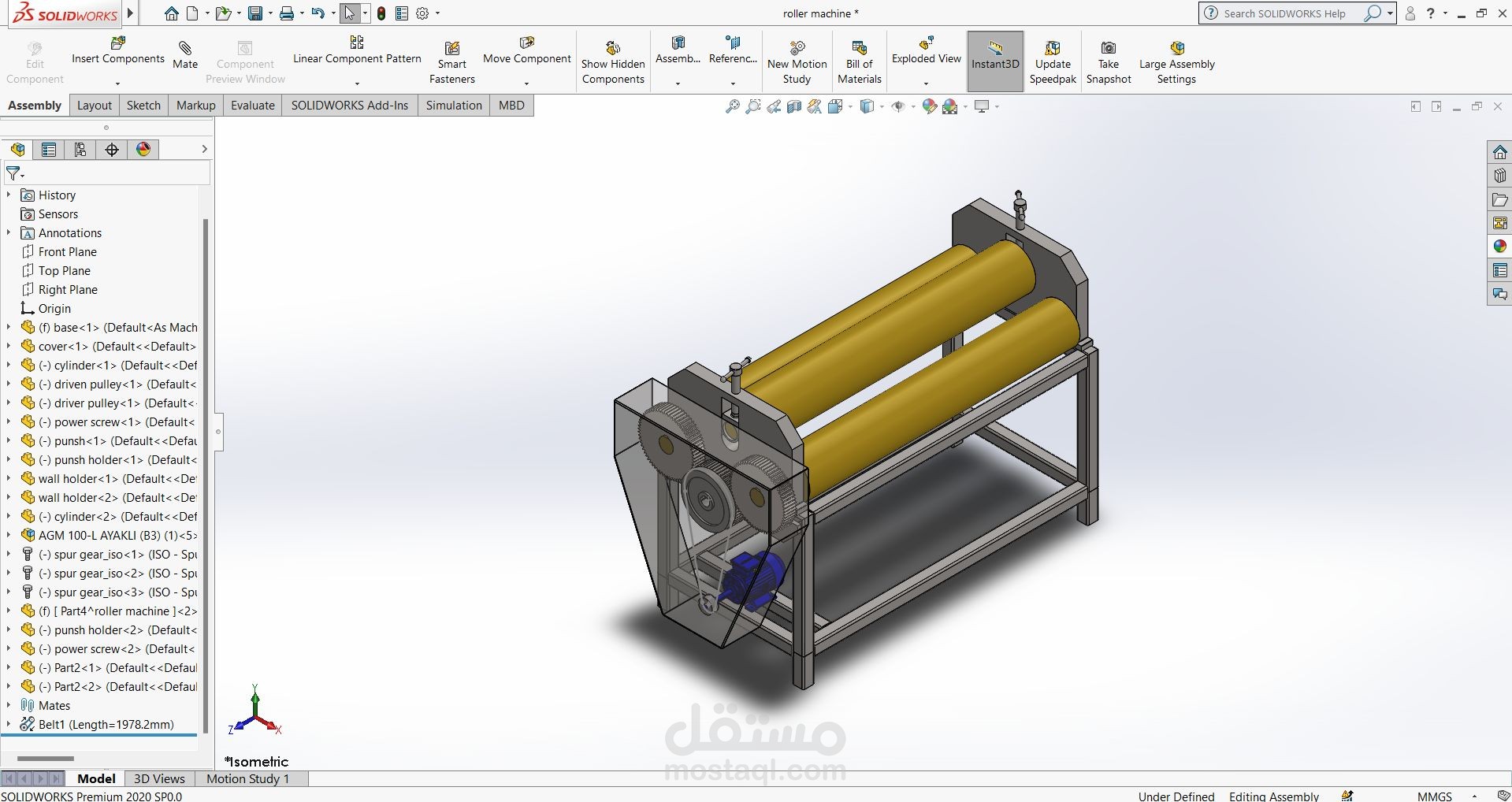

metal rolling machine

تفاصيل العمل

I designed and built a complete metal rolling machine in SolidWorks, transforming a mechanical concept into a fully functional system ready for industrial use.

This machine is engineered to roll and bend sheet metal into circular shapes, and every component was modeled from scratch using advanced SolidWorks tools including Weldments, Sheet Metal, Extrude, Revolve, and full Assembly features.

Key Components Designed:

Base

Wall Holder

Punch Holder

Power Screw

Punch

Cylinder

Pulley Driver

Pulley Driven

Cover

Each part was engineered with a clear mechanical purpose to ensure smooth, reliable operation.

️ Gear Integration:

Using the SolidWorks Toolbox Gear Library, I selected and integrated two ISO spur gears:

ISO Spur Gear 6M 64T (20PA, 80FW)

ISO Spur Gear 6M 56T (20PA, 80FW)

? Material Selection:

AISI 1020 Steel for all primary structural components — chosen for strength, ease of machining, and durability

Brass for the Cylinder and Punch — providing superior wear resistance under pressure

Project Highlights:

This project demonstrates my capabilities in:

Detailed 2D & 3D CAD modeling

Complete mechanical assemblies

Material selection & engineering decision-making

Gear design and kinematic integration

Technical drawings and documentation

Applying real engineering principles to functional design