Chewing Simulator

تفاصيل العمل

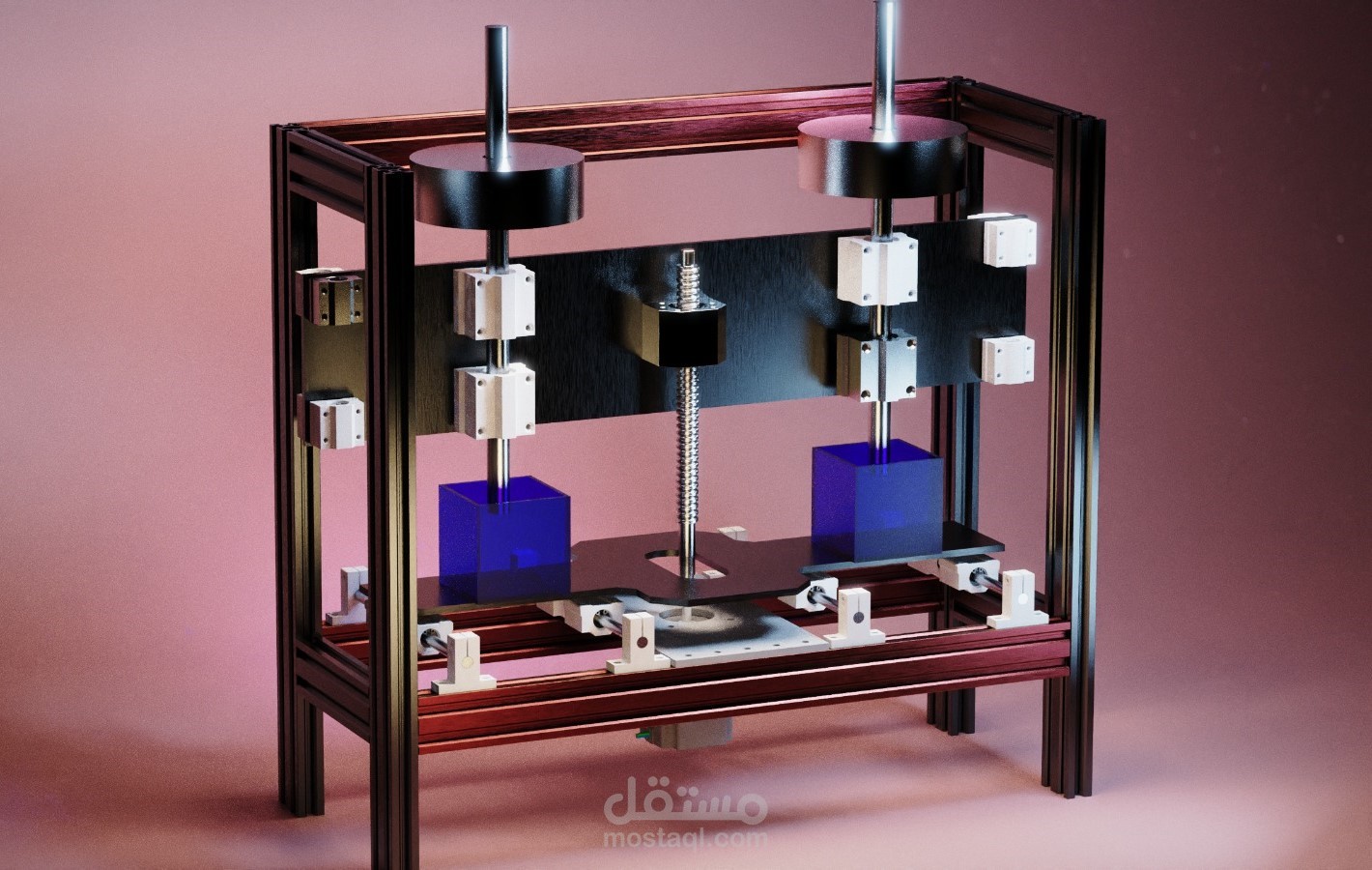

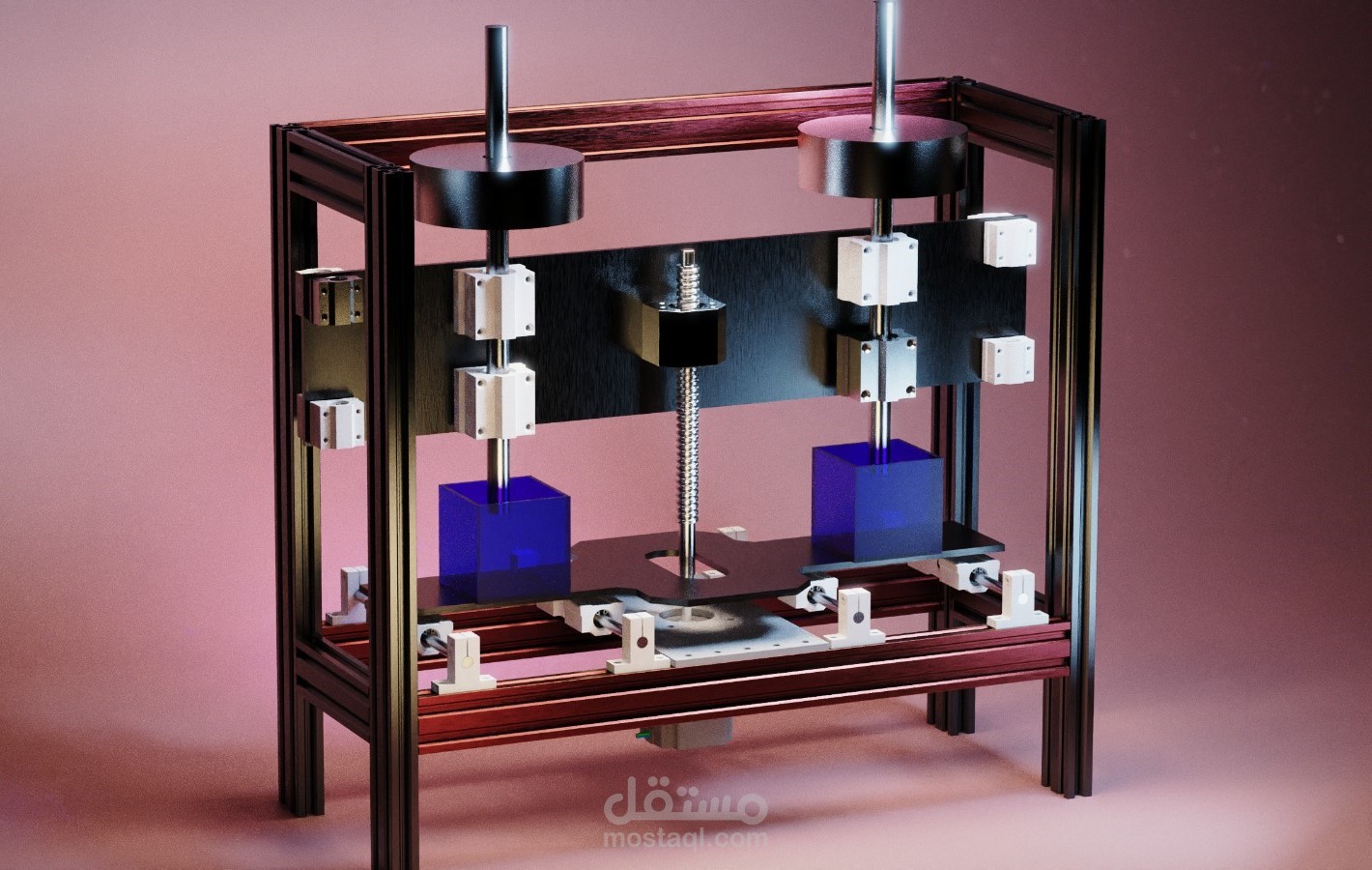

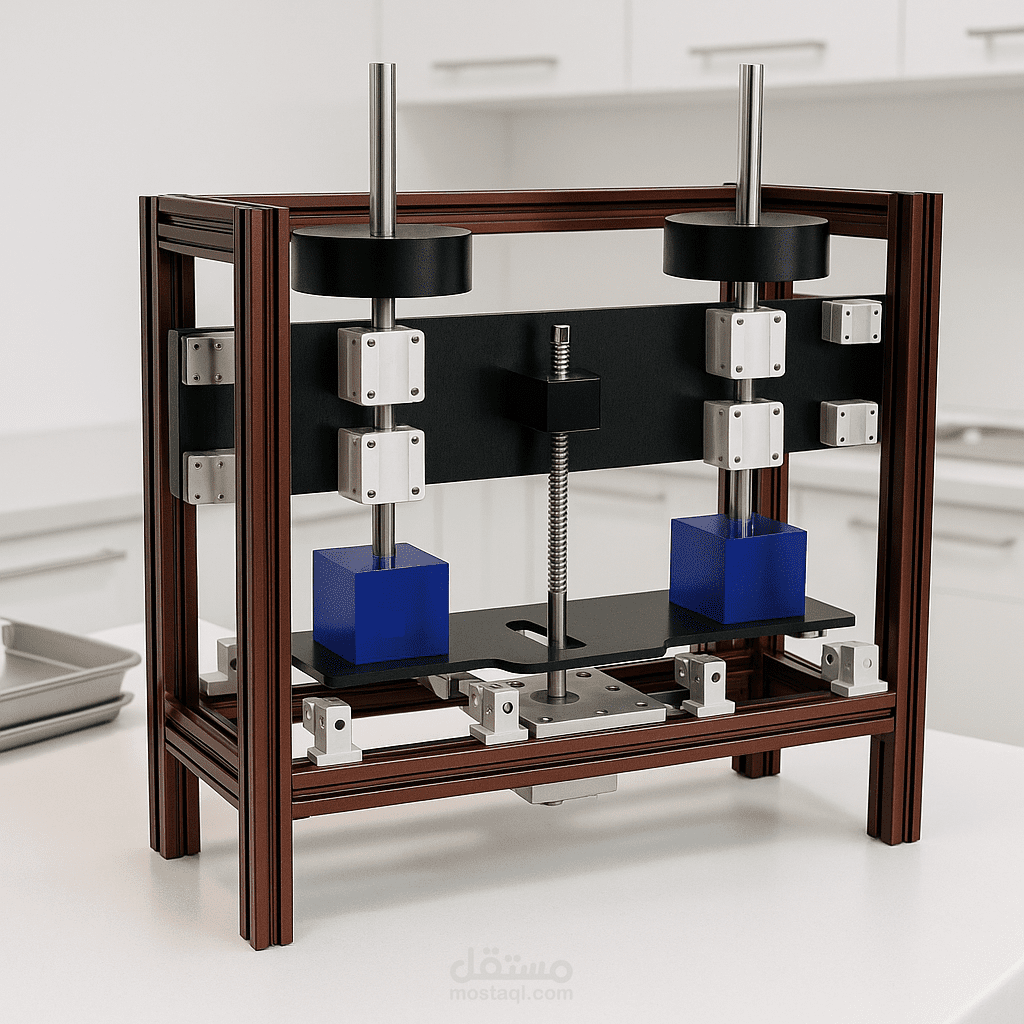

This project was designed and manufactured as a specialized testing machine for dental research, capable of simulating chewing cycles under realistic conditions. It combines precision mechanical design with custom electronics and software to deliver a reliable long-term testing solution.

The structure was built using 2040 aluminum extrusions for strength, rigidity, and modular assembly. The Z-axis is powered by a NEMA 23 (2.8 Nm) stepper motor with a ballscrew mechanism, ensuring smooth motion, minimal friction, and reduced wear. The body is made from 2 mm laser-cut sheet metal with structural bends for lightweight strength, guided by two linear rods and reinforced with 16 mm rods to support weights of up to 15 kg per head for applying controlled forces on dental samples. The Y-axis was fabricated from sheet metal with an acrylic top layer to provide a waterproof barrier, moving along four linear rods and driven by two NEMA 17 stepper motors running in parallel for stability and accuracy.

The testing environment features a clear acrylic sample bath for full visibility of the test area. A continuous water circulation system prevents particle buildup and maintains consistent conditions, while an integrated heater and controller keep the water at 37 °C to replicate human body temperature.

The control system is powered by a custom-modified version of GRBL firmware, adapted specifically for chewing simulation. It supports loop commands for repetitive cycles, unlike standard 3D printer G-code. Flexible scripting allows the operator to adjust speed, displacement, and Y-axis travel with ease. A secondary control board tracks cycle counts and automatically stops the machine once the preset number of cycles is reached.

The machine was successfully manufactured and operated continuously for over one month without issues, delivering consistent and reliable testing performance. The project was recognized in a Q1 scientific publication, where the doctor who owns the device highlighted its effectiveness.