Smart Insulin Pump

تفاصيل العمل

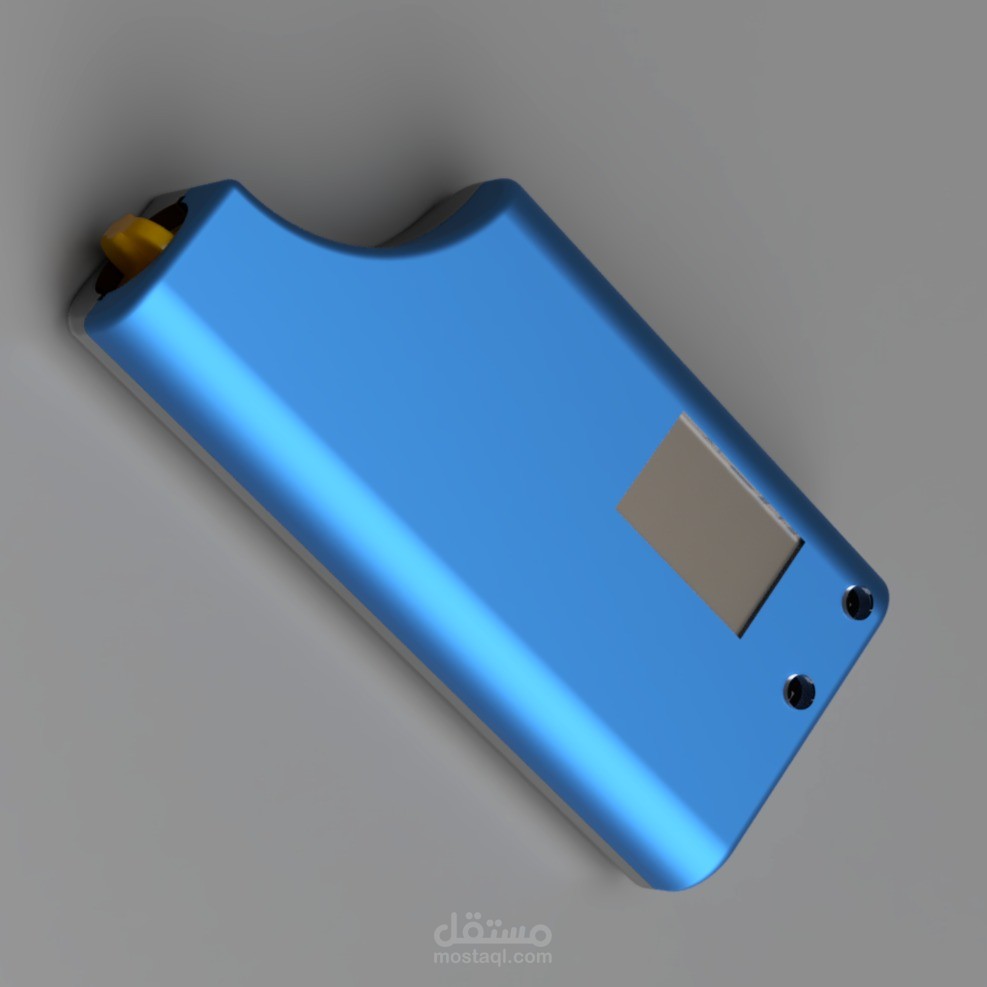

This project was an attempt to design a next-generation insulin pump that is compact, accurate, and patient-friendly. Traditional diabetes care devices are often bulky or unintuitive, so my focus was on creating something ergonomic, reliable, and seamlessly connected.

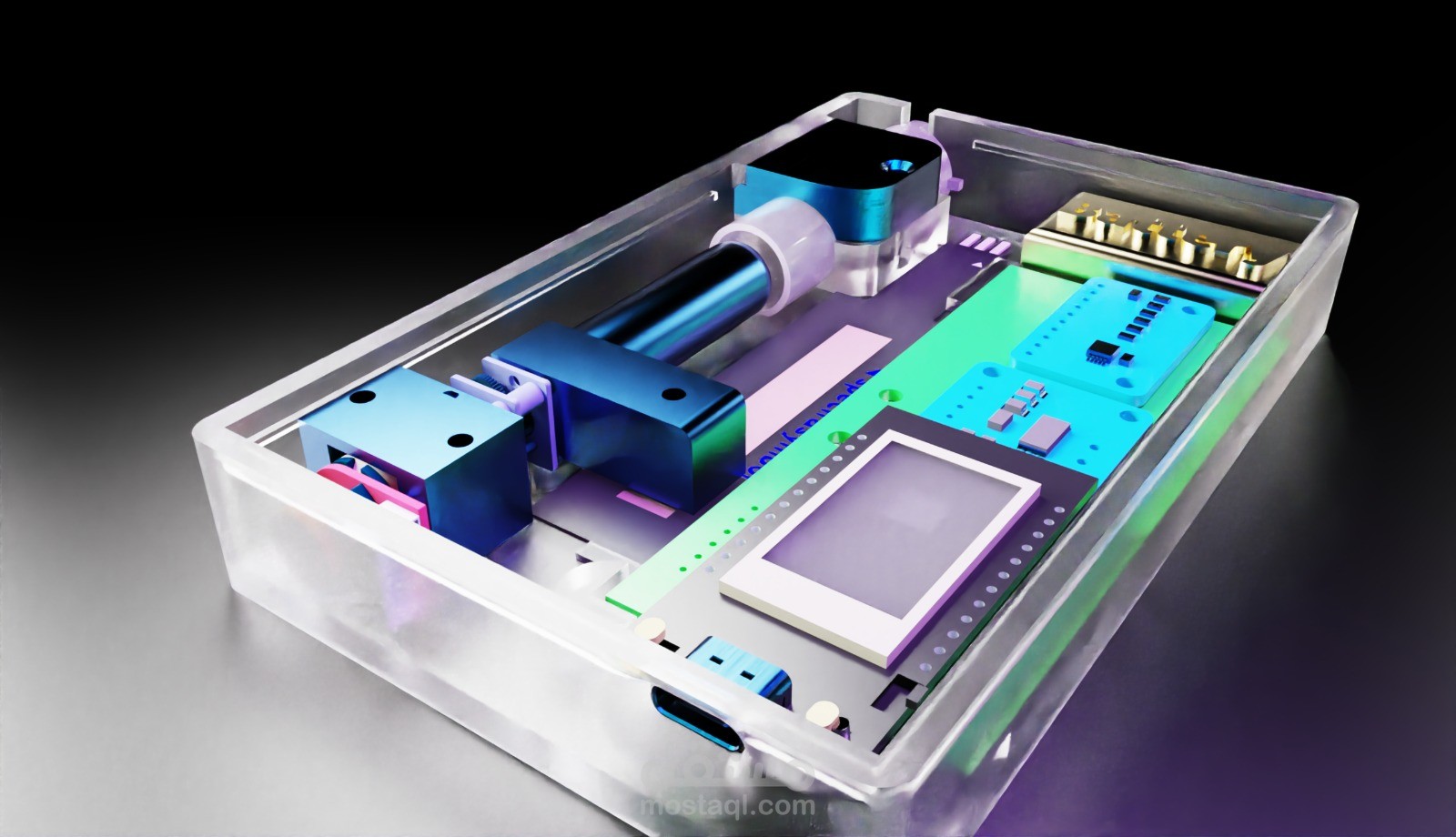

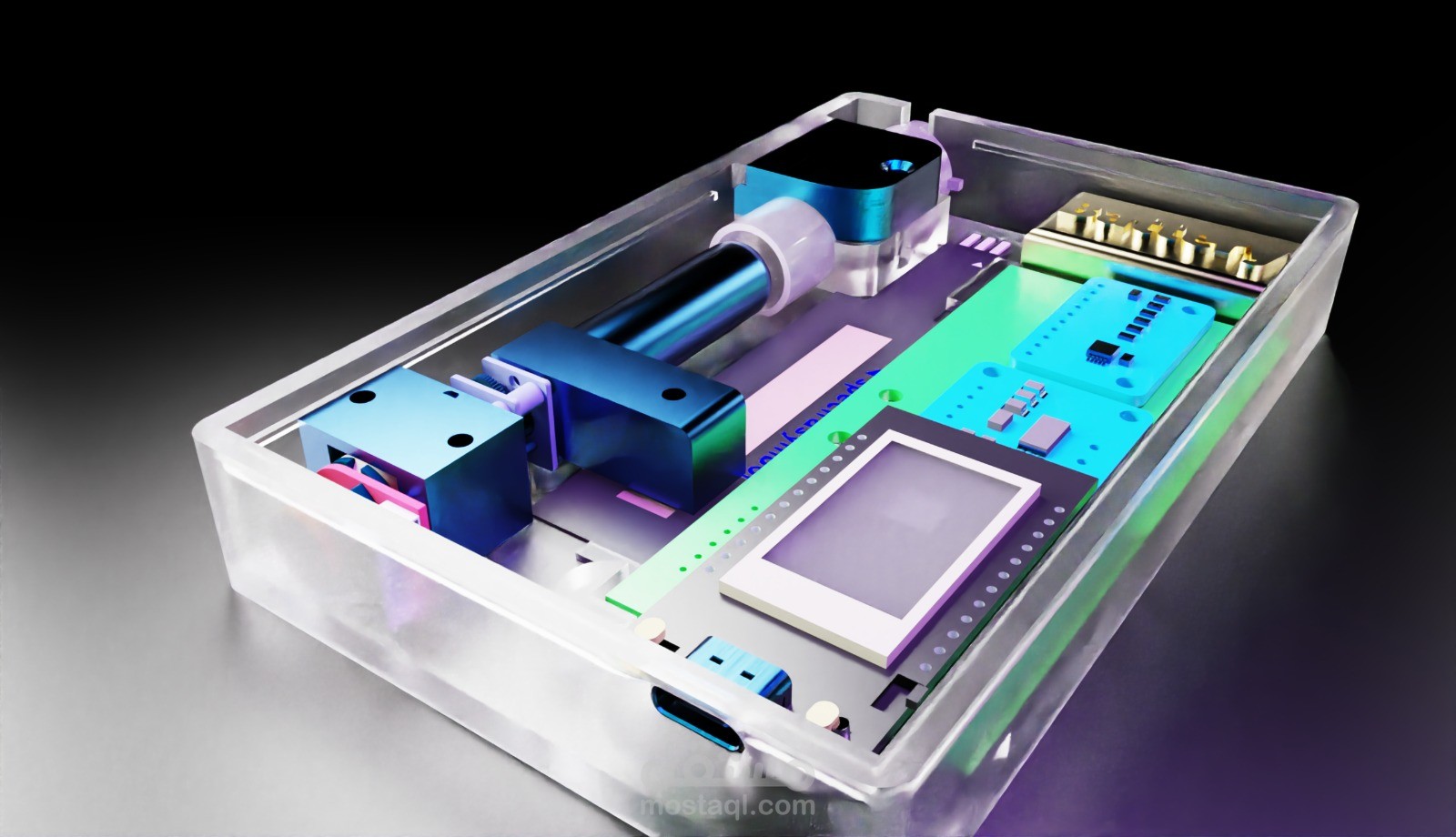

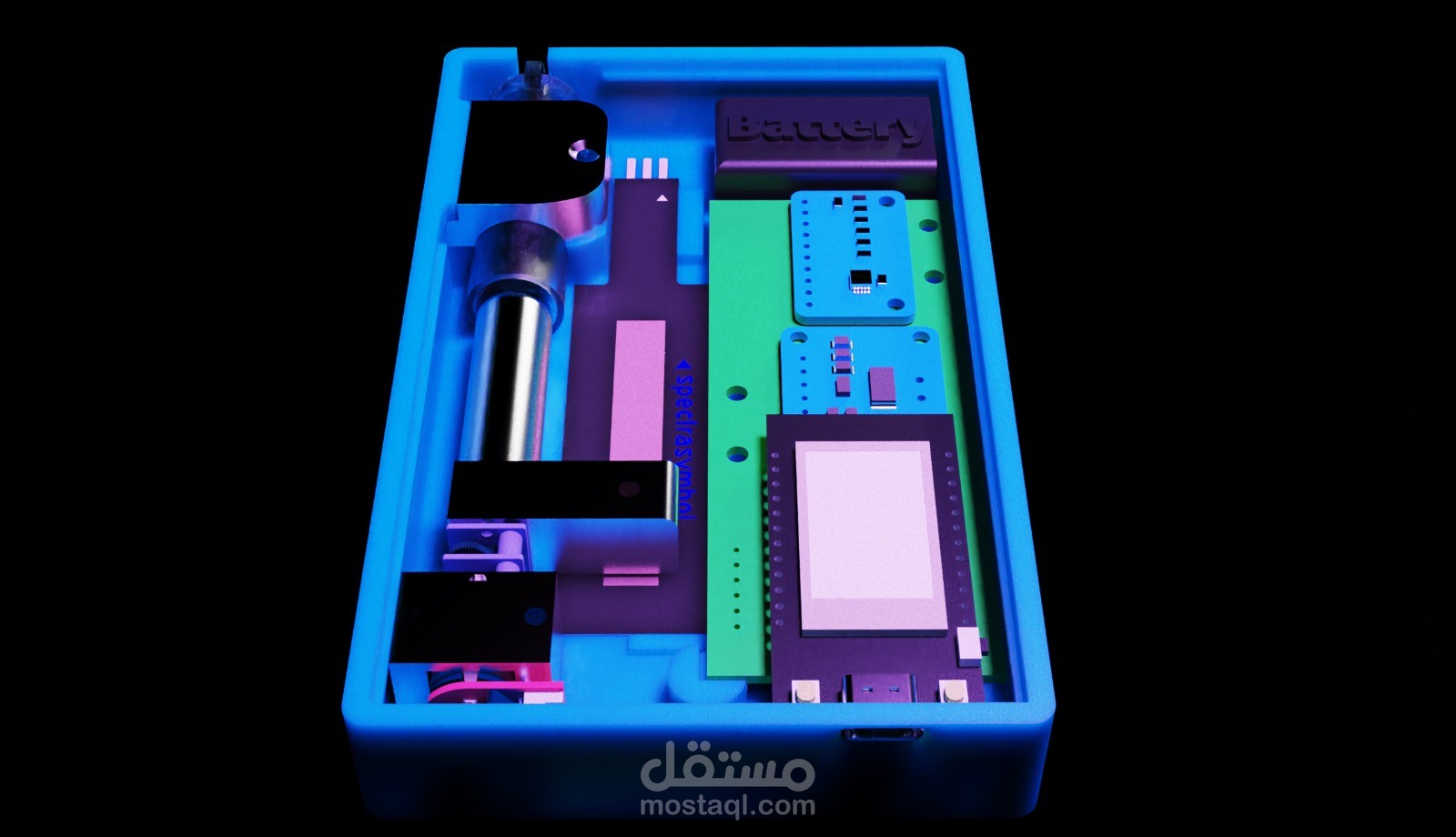

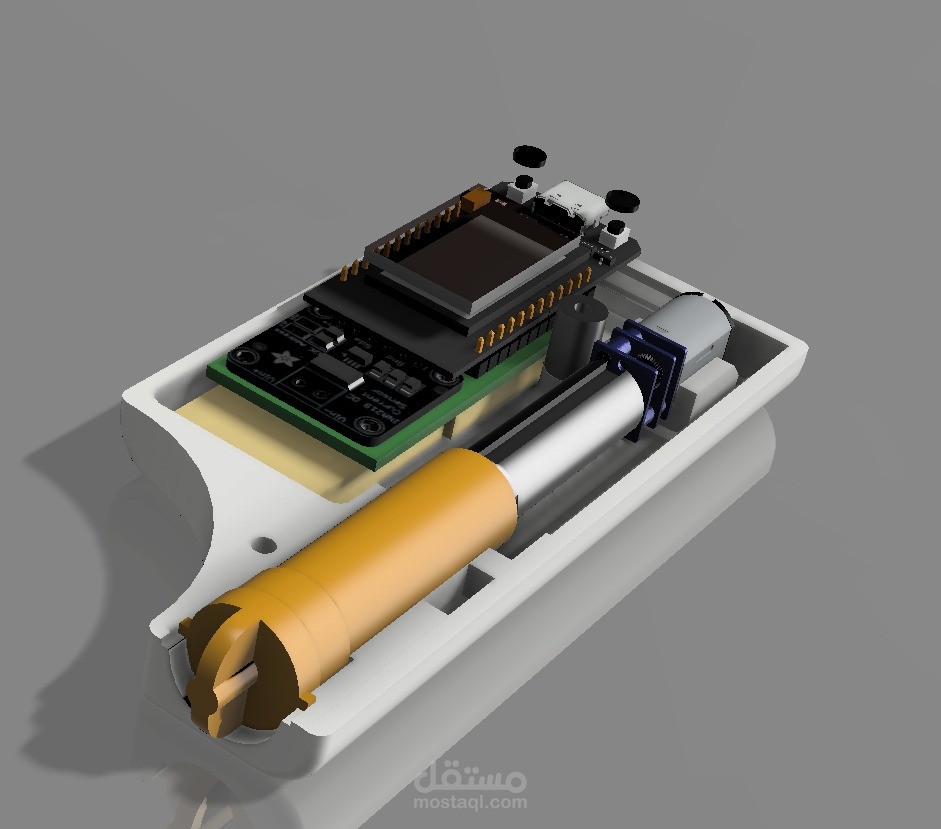

Mechanical Design & Manufacturing

The pump body was produced using both FDM and SLA 3D printing, enabling rapid prototyping while maintaining strength and fine detail where required. Through multiple iterations, the design became smaller and more comfortable to hold.

At the core of the mechanism is a compact motor with a high-ratio gearbox, driving a 3 mm lead screw with a 0.5 mm pitch. This setup provides high torque and precise linear motion, allowing the pump to push on the insulin reservoir plunger with accuracy and consistency.

For the insulin source, I selected the MiniMed 3.0 ml reservoir and infusion set. Using a proven medical-grade cartridge ensured both safety and compliance, while avoiding the need to redesign critical fluid components.

Electronics & Sensors

A custom PCB was built around the ESP32 microcontroller, which provided wireless connectivity and powered a color LCD screen for local interaction.

To ensure safe and reliable operation, multiple sensing methods were integrated:

Motor encoder for precise motion tracking.

High-sensitivity current sensor to detect abnormal resistance (e.g., infusion blockages).

12-bit ADC monitoring for motor load and battery status.

In Version 1, a Spectra Symbol linear potentiometer was added under the plunger to physically confirm motion. However, in Version 2, the design was simplified: encoder feedback and current sensing proved sufficient, allowing the extra sensor to be removed and the pump to be further miniaturized.