SolidWorks Freelancer

تفاصيل العمل

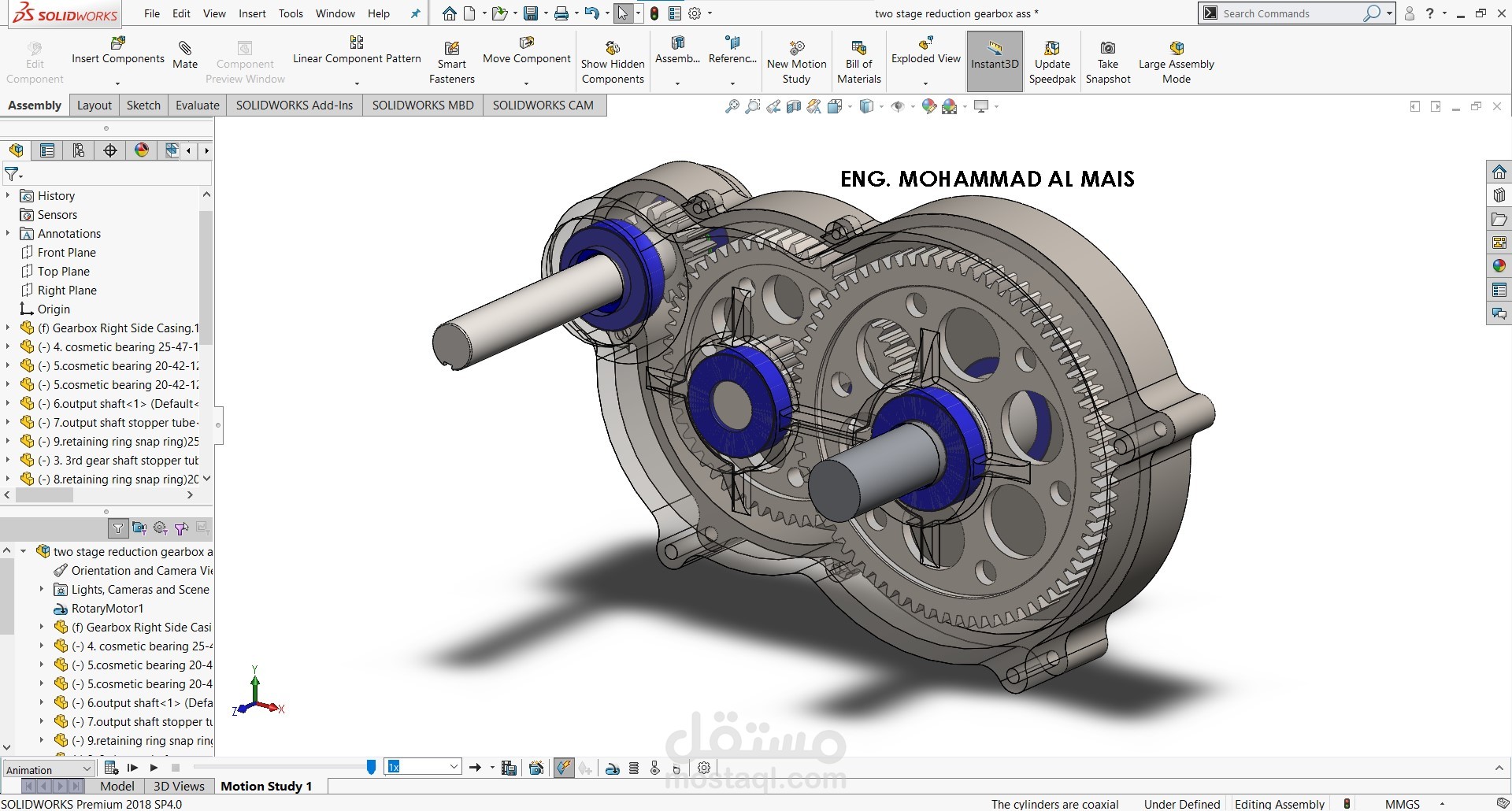

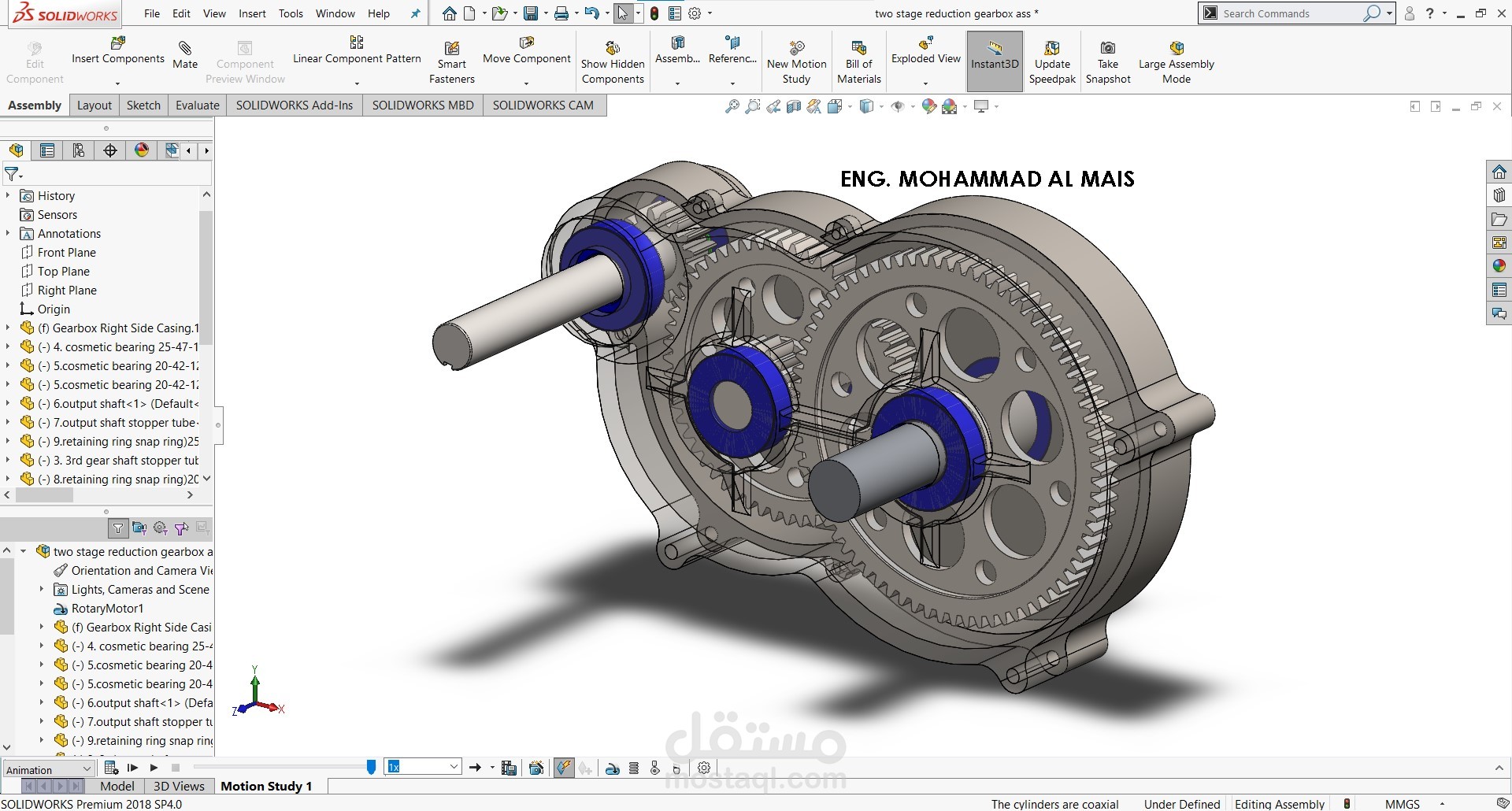

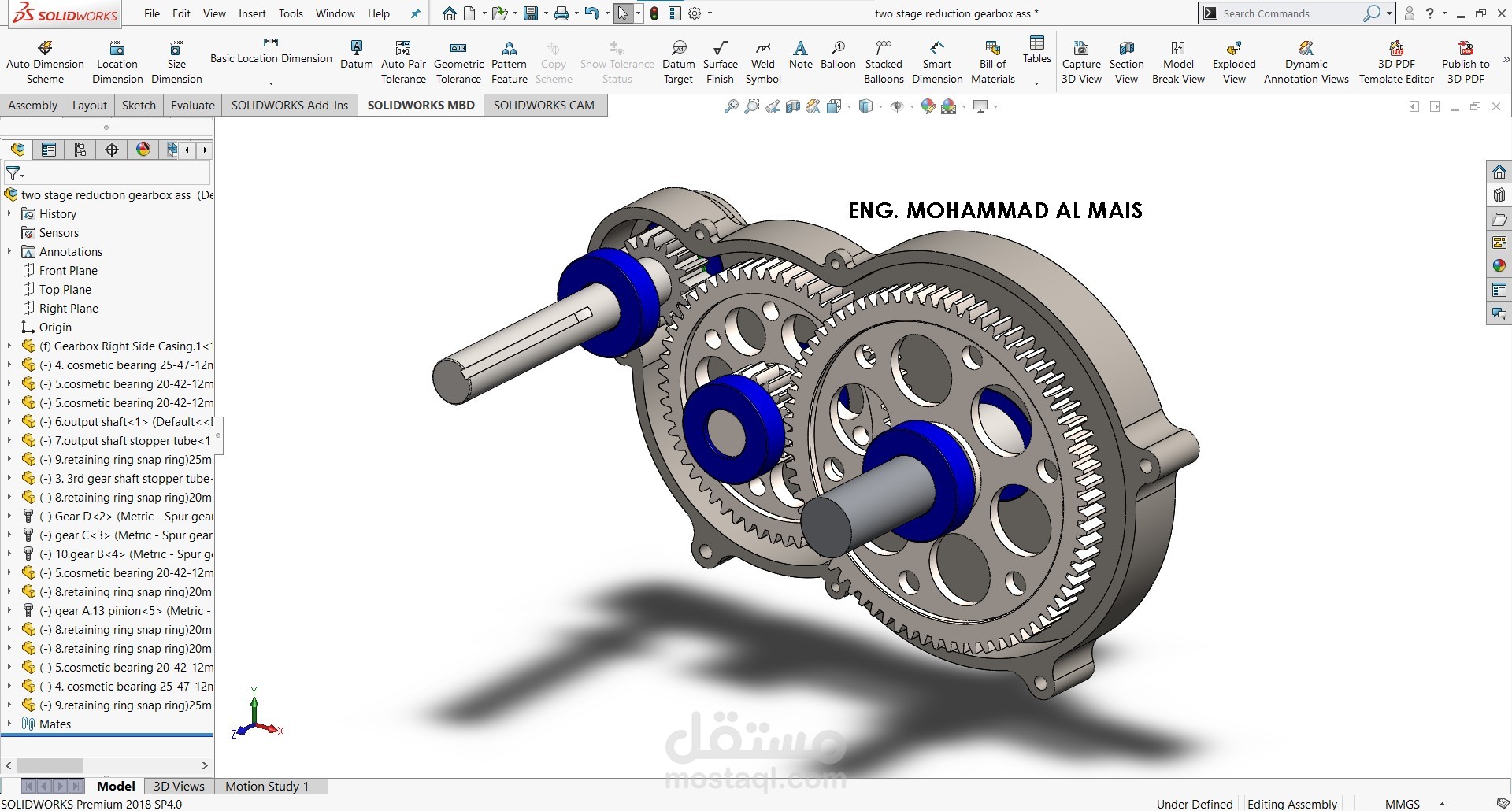

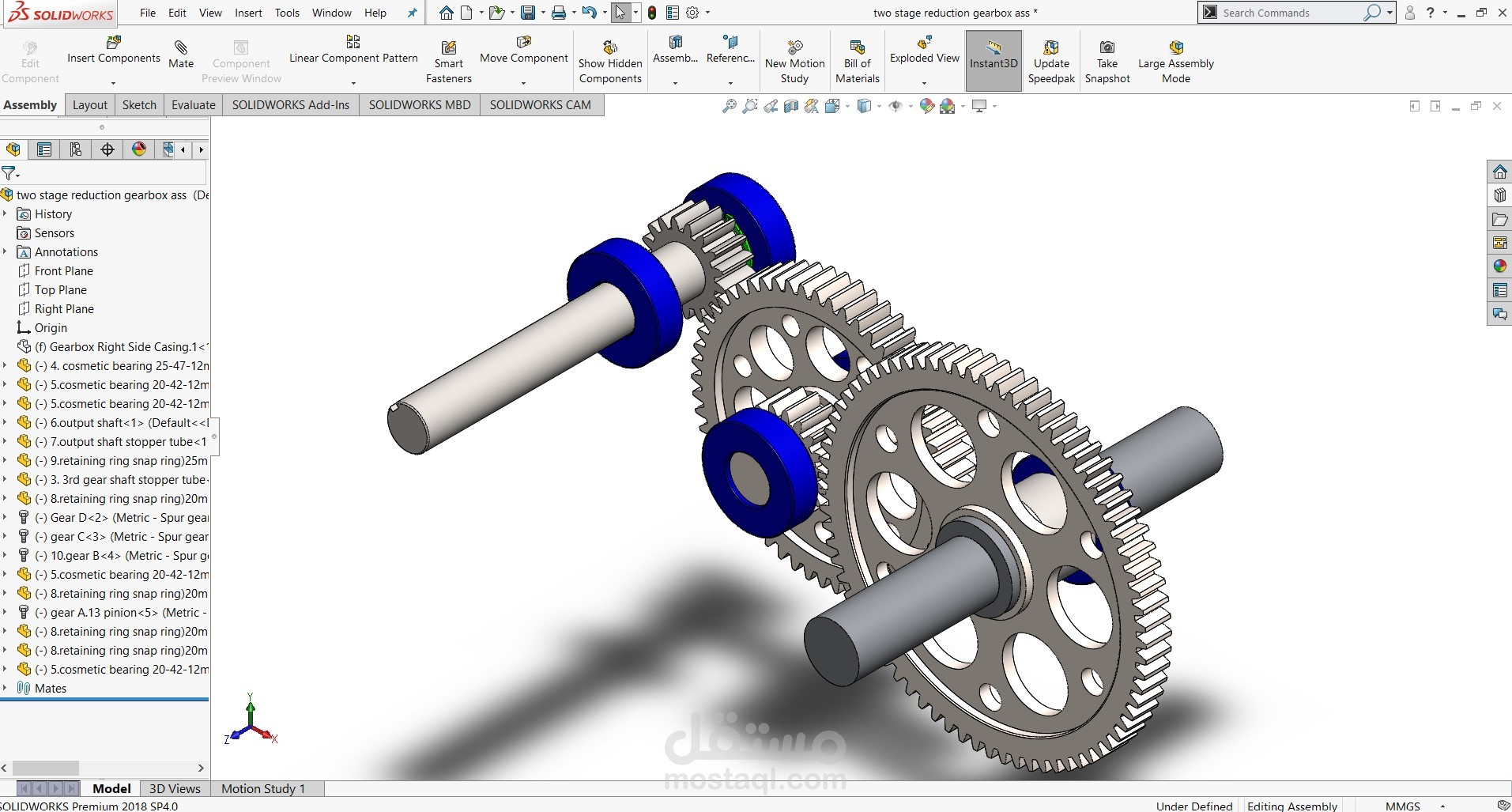

This model represents a two-stage spur gear reduction gearbox designed and assembled in SolidWorks. The gearbox consists of:

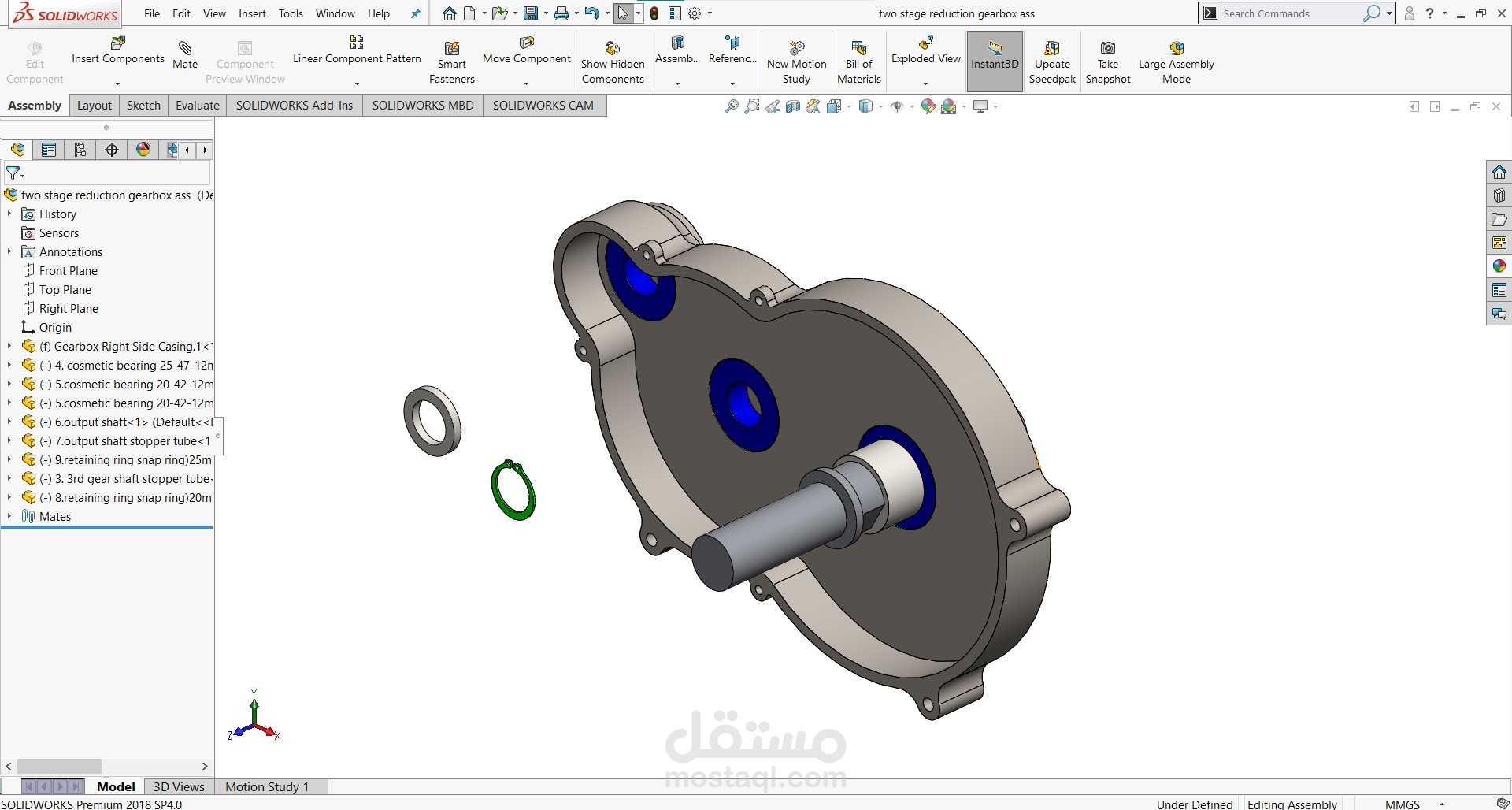

Casing Assembly: Split housing (right and left side casings) designed to enclose the gear train and bearings. The casing includes mounting holes and lightweight cutouts to reduce mass without compromising strength.

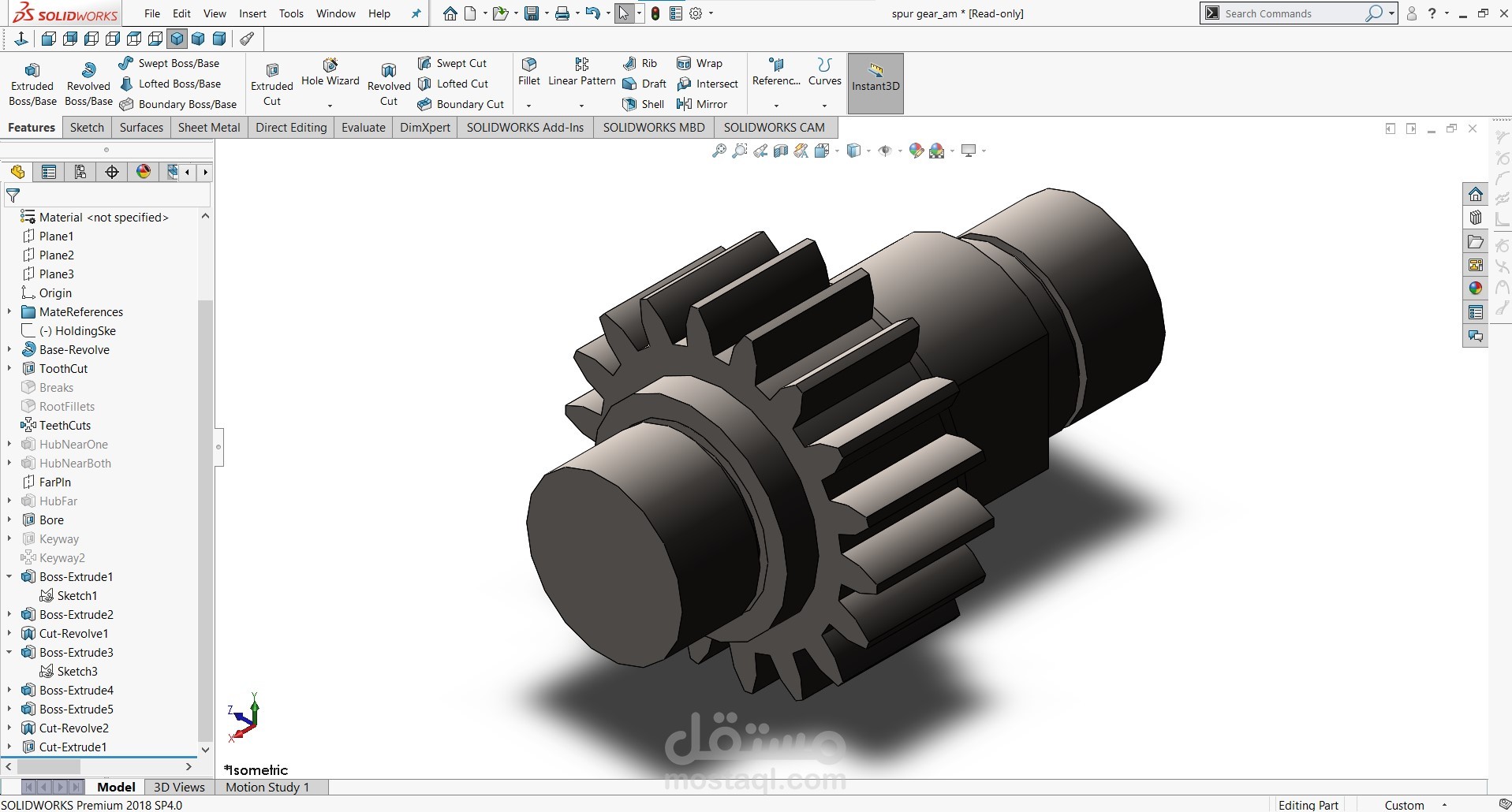

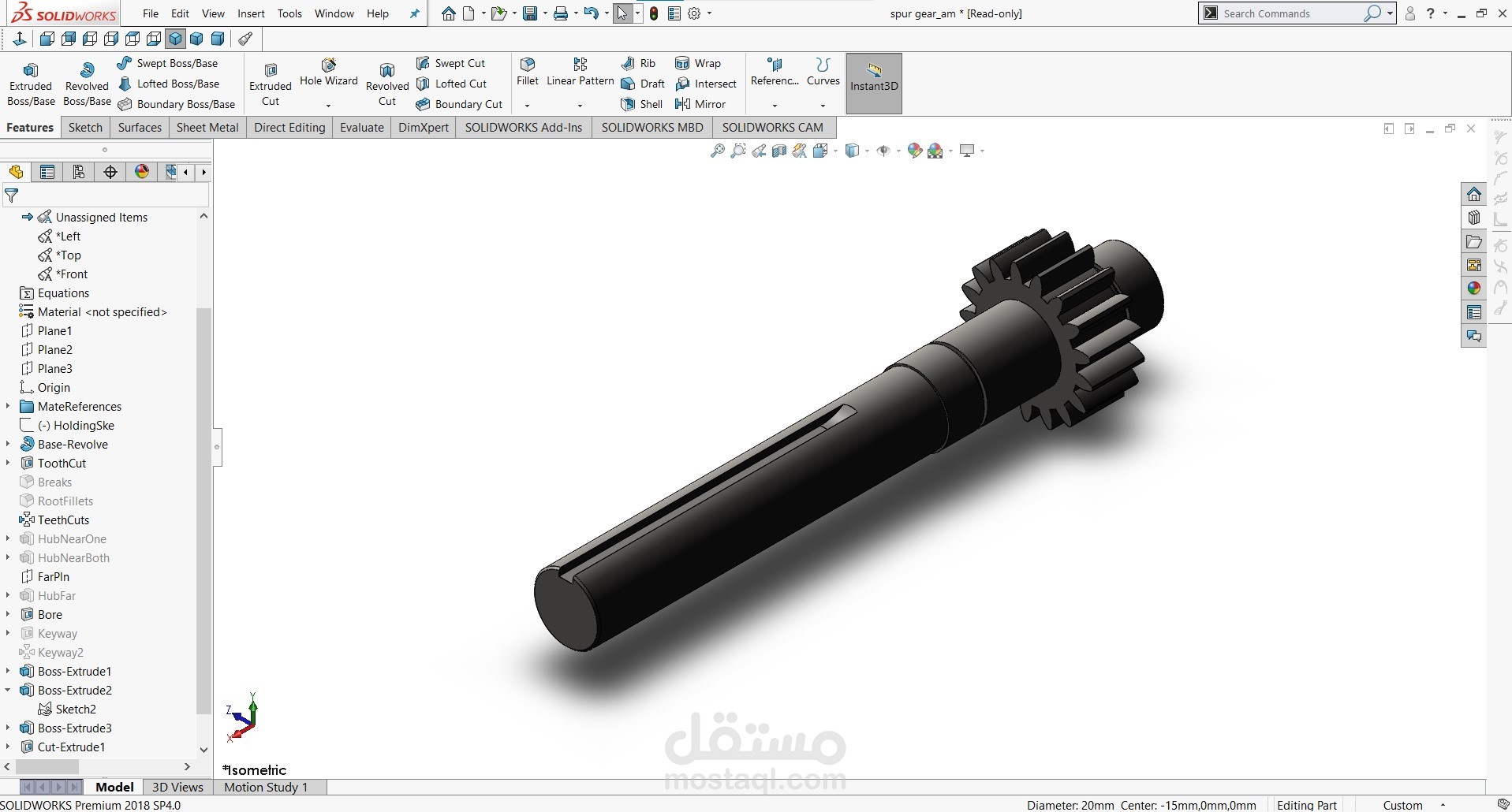

Input Shaft: Mounted on cosmetic bearings with axial retaining rings. It transmits power to the first-stage gear.

First-Stage Gear Pair: A small pinion gear mounted on the input shaft drives a larger gear, providing the first reduction ratio.

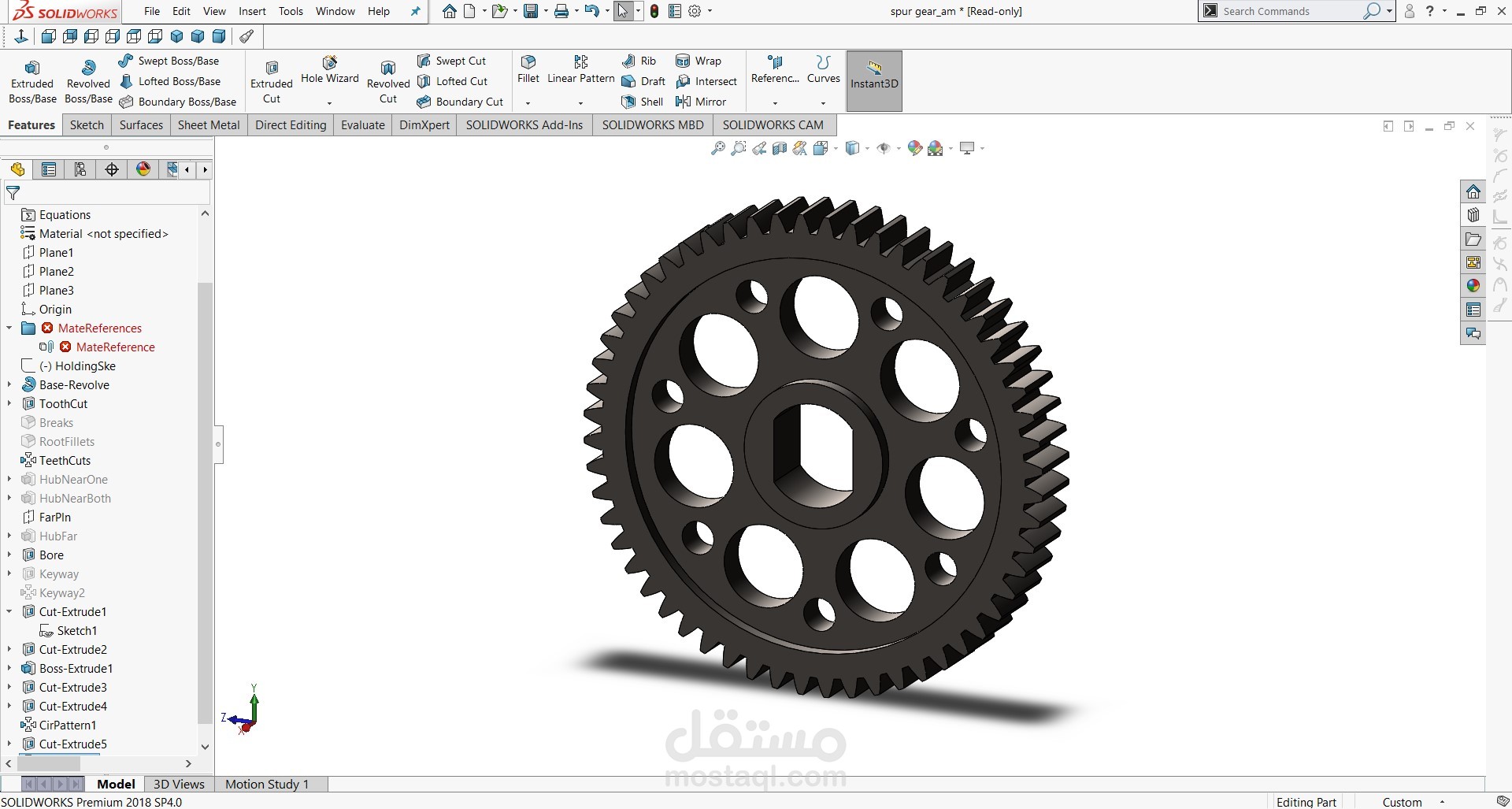

Second-Stage Gear Pair: The driven gear from the first stage is coaxially mounted with a smaller pinion, which engages with the final output gear, achieving the second reduction stage.

Output Shaft: Supported by bearings and secured with snap rings to ensure correct alignment and minimize axial play.

Bearings and Retainers: Standard cosmetic bearings and retaining rings ensure smooth rotation and proper shaft positioning.

The overall gearbox achieves a compound gear reduction by multiplying the individual stage ratios, resulting in significant torque amplification and reduced output speed. This design is optimized for applications requiring high torque transmission and compact packaging, such as robotics, conveyors, and industrial machinery.