Design, Optimization, and Simulation of a Mechanical Test Fixture

تفاصيل العمل

This project showcases my advanced proficiency in mechanical design, computer-aided design (CAD), and computer-aided engineering (CAE), focusing on the end-to-end development of a high-precision mechanical test fixture. The goal was to design a reliable and modular fixture capable of withstanding complex loading conditions while ensuring accurate alignment and repeatability during mechanical testing.

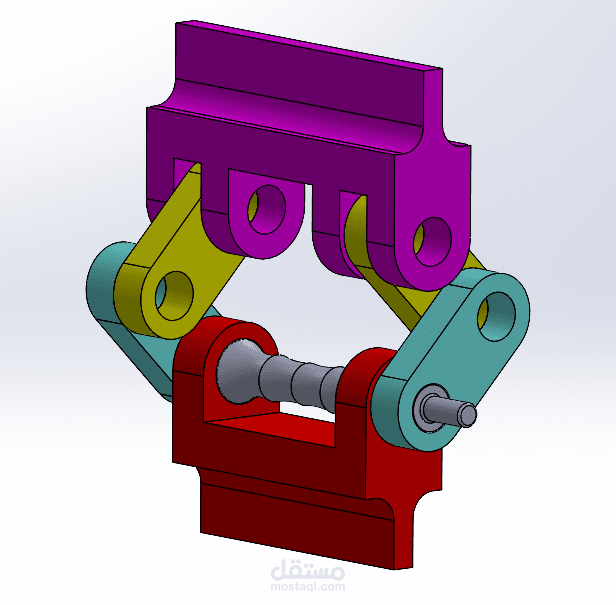

Using parametric modeling in SolidWorks (or Fusion 360 / CATIA / any CAD software of your choice), I developed a detailed 3D model incorporating ergonomic and manufacturability considerations. The fixture was designed for compatibility with standard universal testing machines (UTMs) and customized for specific specimen geometries.

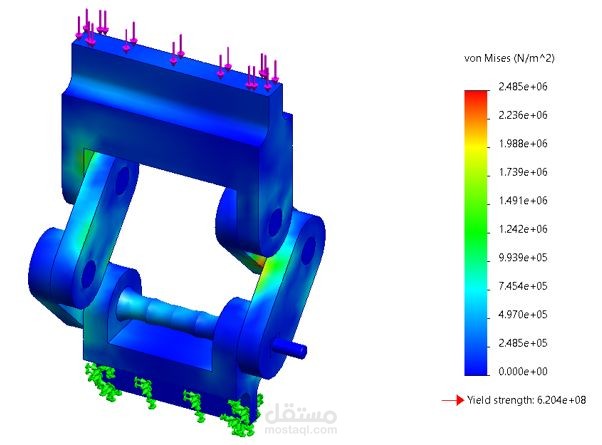

The design underwent a comprehensive finite element analysis (FEA) using Abaqus to simulate stress distribution, deformation, and failure modes under various load cases, including tensile, compressive, and bending scenarios. I applied realistic boundary conditions and material properties to ensure simulation fidelity.

To enhance performance, I implemented design optimization techniques, such as topology optimization and parametric sensitivity studies, to reduce weight while maintaining structural integrity and stiffness. The final design achieved an optimal balance between strength, cost-effectiveness, and ease of assembly.

This project demonstrates my integrated skillset in mechanical system design, structural simulation, and performance-driven optimization, reinforcing my capability to take a concept from initial idea through digital prototyping and virtual testing—all the way to manufacturing readiness.