defected items analysis

تفاصيل العمل

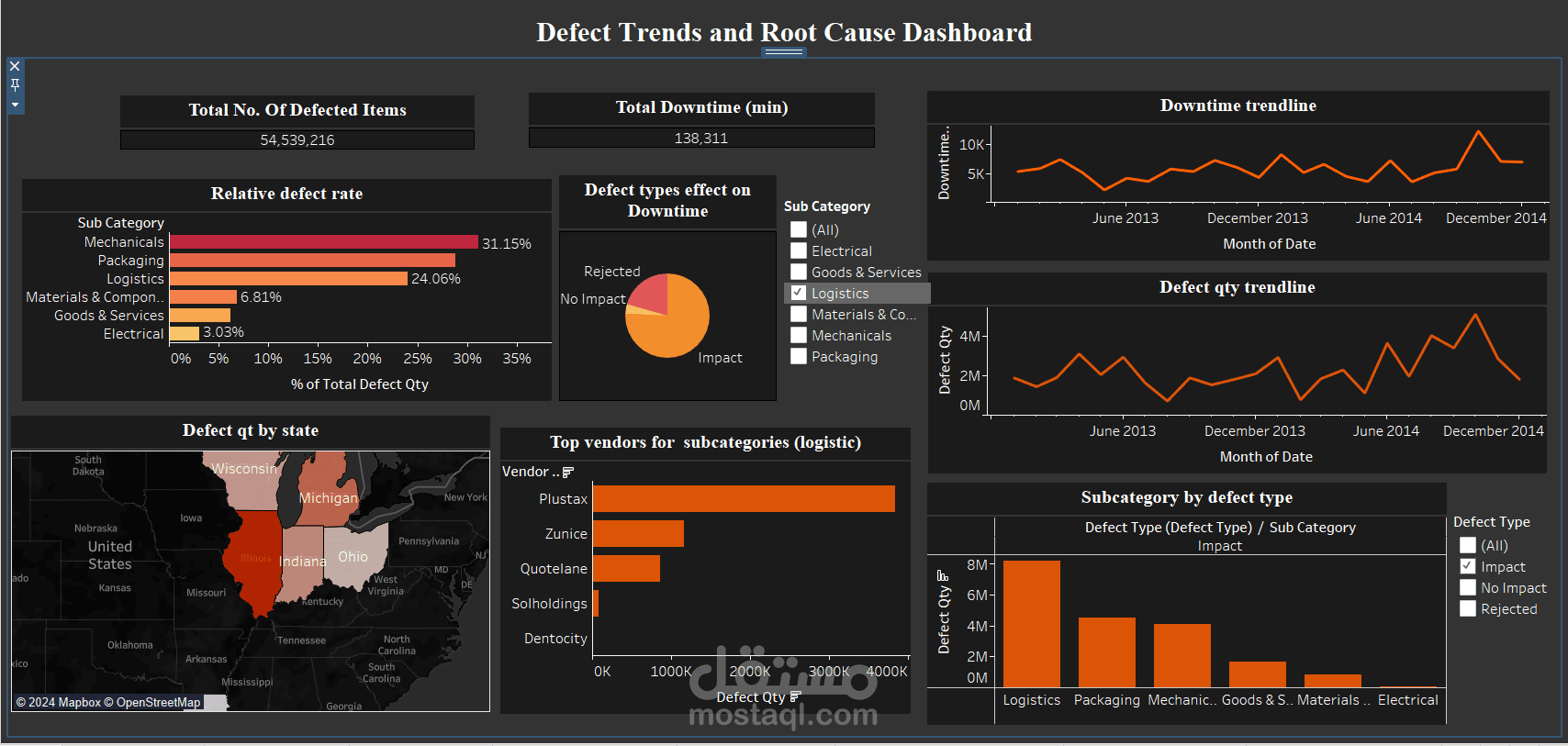

A Defected Items Dashboard is a visual representation of quality control metrics and performance indicators related to product defects. It provides a centralized view of defect trends, root causes, and corrective actions, empowering businesses to make data-driven decisions for quality improvement.

Key Components and Visualizations:

Total No. of Defected Items and Total Downtime:

These key performance indicators (KPIs) provide an overview of the overall defect and downtime situation.

Downtime trendline: A line chart visualizes the trend of downtime over time.

Relative Defect Rate:

A bar chart shows the distribution of defects across different subcategories.

Defect Types Effect on Downtime: A pie chart illustrates the impact of different defect types on downtime.

Defect Qty Trendline:

A line chart tracks the trend of defect quantity over time.

Defect Qty by State:

A map visualization shows the distribution of defects across different states.

Top Vendors for Subcategory (Logistic):

A bar chart highlights the top-performing vendors for a specific subcategory.

Subcategory by Defect Type:

A bar chart visualizes the distribution of defect types across different subcategories.

Possible Tool Used:

Based on the appearance and functionality, it's likely that this dashboard was created using a business intelligence tool such as Tableau. These tool offer powerful data visualization capabilities and can connect to various data sources (e.g., databases, spreadsheets) to create interactive dashboards.

Potential Insights and Actions:

Identify Root Causes: By analyzing the defect types and their impact on downtime, you can pinpoint the root causes of defects and implement corrective actions.

Monitor Trends: Track trends in defect rates and downtime over time to identify potential issues and take preventive measures.

Improve Supplier Performance: Monitor the performance of suppliers and identify underperforming vendors.

Optimize Manufacturing Processes: Analyze the impact of different manufacturing processes on defect rates and downtime.

Enhance Quality Control: Implement stricter quality control measures to reduce defects and improve product quality.