CNC machine using XMC motion controller

تفاصيل العمل

Our automation project aims to enhance the efficiency, precision, and flexibility of a cutting machine using advanced technology components. We will utilize the LSIS XMC motion controller for seamless motion control and coordination of various machine functions. EtherCAT protocol will facilitate high-speed communication between the motion controller and servo motors, ensuring precise positioning and motion control.

Key Components and Features:

LSIS XMC Motion Controller: The LSIS XMC motion controller will serve as the central control unit for the cutting machine. It will manage inputs and outputs, execute motion profiles, and coordinate the overall operation of the system.

EtherCAT Protocol: EtherCAT will be used as the communication protocol between the motion controller and servo motors. This protocol offers real-time communication capabilities, enabling fast and reliable data exchange for precise control of motion.

Servo Motors: High-performance servo motors will be employed for accurate positioning and motion control of the cutting machine. The EtherCAT protocol will ensure synchronized operation and precise coordination of multiple axes.

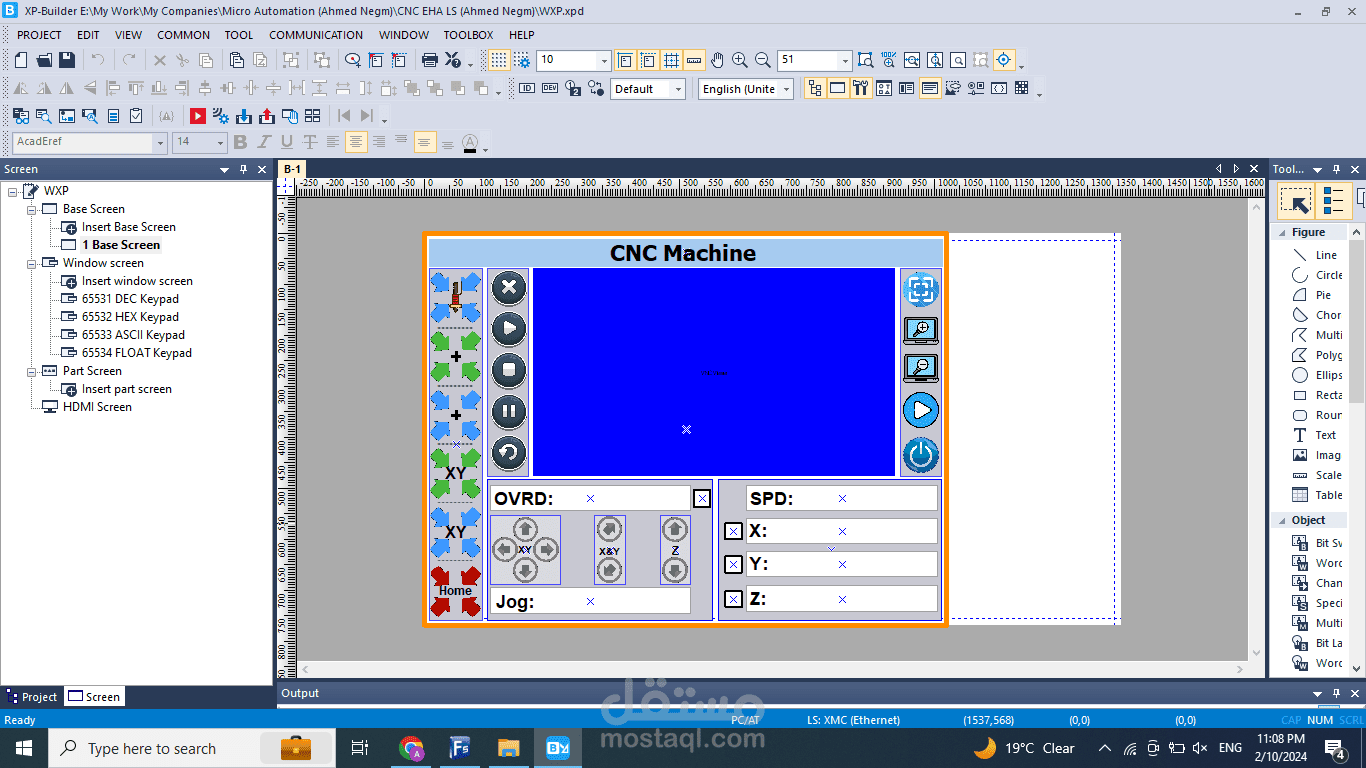

HMI with USB Interface: An intuitive Human-Machine Interface (HMI) will be designed to provide operators with a user-friendly interface for controlling the cutting machine. The HMI will feature a USB interface, allowing operators to input G code instructions via USB for seamless integration into the cutting process.

G Code Compatibility: The cutting machine will support G code instructions, a standard programming language used in CNC (Computer Numerical Control) machining. Operators can easily input G code programs via USB to specify cutting dimensions, paths, and other parameters.

Motion Profile Optimization: The LSIS XMC motion controller will be programmed to execute optimized motion profiles, ensuring smooth and efficient cutting operations. Motion profiles will be tailored to minimize vibration and enhance cutting quality.

Alarm Management and Diagnostics: The motion controller will include built-in alarm management systems to detect and notify operators of any anomalies or faults in the cutting process. Additionally, remote access capabilities will enable remote diagnostics and troubleshooting for efficient maintenance and support.